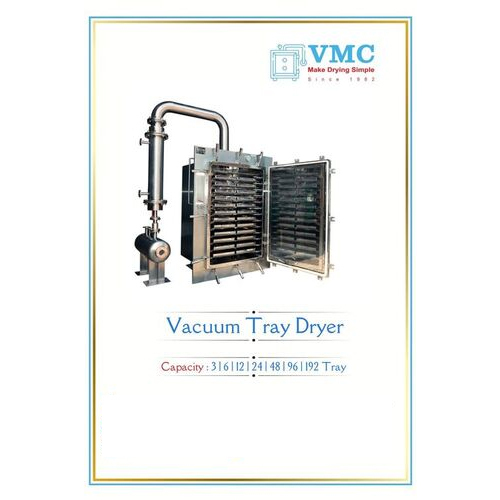

Vacuum Tray Dryer

1150000 INR/Number

Product Details:

- Usage Industrial

- Color Sliver

- Material Stainless Steel

- Voltage 220 Volt (v)

- Warranty 1 Year

- Click to View more

X

Vacuum Tray Dryer Price And Quantity

- 1 Number

- 1150000 INR/Number

Vacuum Tray Dryer Product Specifications

- Sliver

- Industrial

- 1 Year

- 220 Volt (v)

- Stainless Steel

Vacuum Tray Dryer Trade Information

- Jharkhand

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Dryers' category

VITAL MACHINERY CORPORATION

GST : 24AEBPP4472J1ZE

GST : 24AEBPP4472J1ZE

Unit -1 : Plot No. 4796, Near Lyka Lab, GIDC Estate, Opp. Water Tank, Ankleshwar - 393002, Gujarat, India

Phone :07971191130

Unit -2 : Plot no. 7509, Near Karmatur Chokdi, Ankleshwar GIDC, Ankleshwar, Bharuch, Gujarat - 393002.

Sister concern company :- Vijay Enterprise

Address :- Plot no. 4915, GIDC Estate Ankleshwar, Bharuch, Gujarat - 393002.

|

VITAL MACHINERY CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |